The rotator thrust bearing must be maintained regularly by cleaning and applying grease. This will ensure a longer service life.

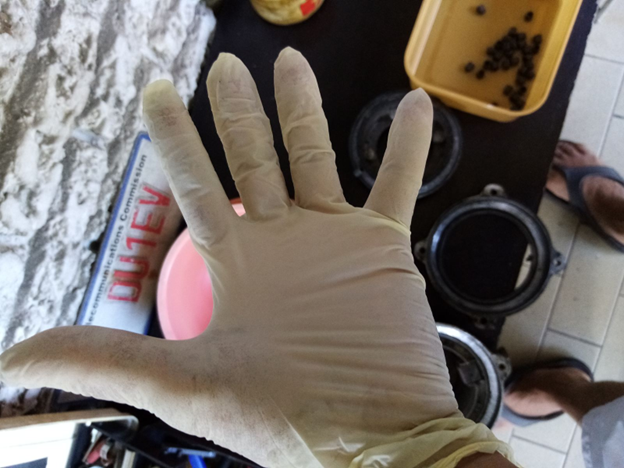

I recommend wearing rubber gloves so that the grease and grime will not get stuck on your fingernails.

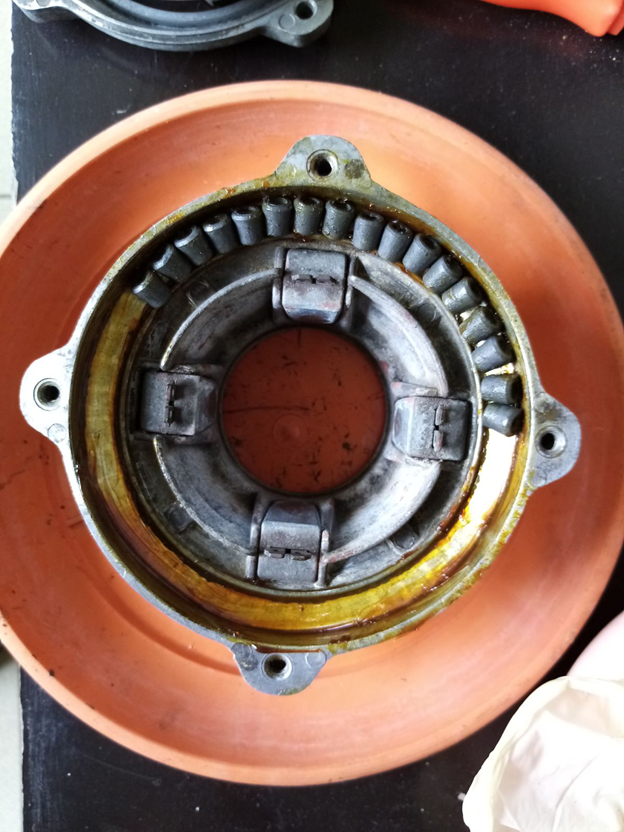

Place the rotator thrust bearing in a deep dish so that bearings will not get lost when you dis-assemble the unit. Loosen the retaining bolts of the thrust bearing.

After loosening the bolts, you may remove the top cap. As you can see, one of the bearings fell off and it was safely caught in the dish or pan.

Then remove the inserted rotating dish which is sandwiched between the two levels of bearings. This will reveal the lower-level bearings. As you can see, some of the bearings fell off and it was safely caught in the dish or pan.

Remove the bearings and place them in appropriate containers. Since there are two sets of bearings, use two distinct containers.

Clean the assembly with a rag. Remove as much of the grease and grime.

After cleaning, apply grease on the rails for the bearings. Molybdenum grease (black) is suggested. Unfortunately for me, motor grease was the only grease available in my garage. For those who live in countries which have a harsh winter, please use the appropriate grease for freezing temperatures.

Afterwards, place the assembly on the deep dish and re-insert the bearings in between the rails.

Apply grease to the inserted rotating dish that was sandwiched between the two levels of bearings. Then re-insert the other set of bearings.

Re-attach the top cap and tighten the bolts.

Test the thrust bearing. If there is too much friction, you may have to apply more grease.

Thank you for reading my article. I wish you luck in your thrust bearing maintenance.